Brief introduction

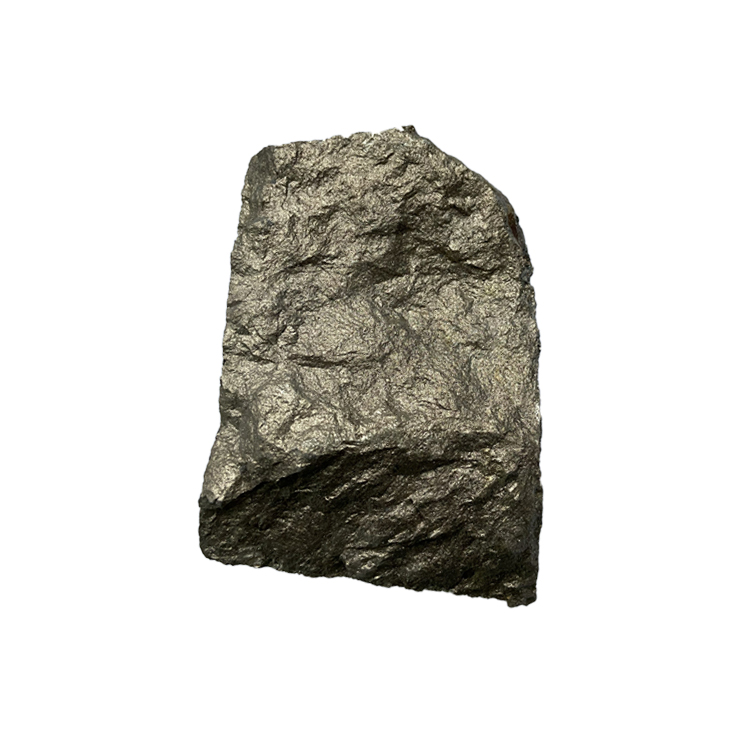

Product Name: Copper Magnesium Master Alloy

Other Name: CuMg master alloy ingot

Mg content: 15%, 20%, 25%, customized

Shape: irregular ingots

Package: 1000kg/drum

| Spec | Chemical Composition % | |||||

| Range | ≤ | |||||

| Cu | Mg | Fe | P | S | ||

| CuMg20 | Bal. | 17-23 | 1.0 | 0.05 | 0.05 | |

- Alloy Production: Copper-magnesium master alloy is mainly used to produce copper-magnesium alloy, which is famous for its high strength, corrosion resistance and lightweight characteristics. These alloys are particularly valuable in applications requiring high mechanical properties, such as in the aerospace and automotive industries, where reducing weight while maintaining strength is critical.

- Electrical Applications: Copper-magnesium alloys are used in electrical applications due to their excellent electrical conductivity and mechanical properties. Adding magnesium increases the strength of the alloy without significantly compromising its electrical conductivity, making it suitable for use in electrical connectors, wires and components in power distribution systems. This application is critical to ensuring reliable performance of electrical systems.

- Marine Applications: The corrosion resistance of copper-magnesium alloys makes them ideal for marine applications. These alloys are commonly used in shipbuilding, offshore structures and marine hardware, where exposure to salt water and harsh environments can cause the material to degrade rapidly. The enhanced corrosion resistance provided by magnesium helps extend the service life of components in these challenging conditions.

- Heat Exchangers: Copper-magnesium alloys are also used in the manufacture of heat exchangers because of their excellent thermal conductivity and corrosion resistance. These properties make them suitable for applications in HVAC systems, refrigeration and industrial processes where efficient heat transfer is required. Using copper-magnesium alloys in heat exchangers helps improve energy efficiency and performance.

We are manufacturer, our factory is located in Shandong, but we can also provide one stop purchasing service for you!

T/T(telex transfer), Western Union, MoneyGram, BTC(bitcoin), etc.

≤25kg: within three working days after payment received. >25kg: one week

Available, we can provide small free samples for quality evaluation purpose!

1kg per bag fpr samples, 25kg or 50kg per drum, or as you required.

Store the container tightly closed in a dry, cool and well-ventilated place.

-

Aluminum Lithium Master Alloy AlLi10 ingots man...

-

Magnesium Zirconium Master Alloy MgZr30 ingots ...

-

Copper Chromium Master Alloy CuCr10 ingots manu...

-

Aluminum Beryllium Master Alloy AlBe5 ingots ma...

-

Chromium Molybdenum alloy | CrMo43 ingots | man...

-

Copper Arsenic Master Alloy CuAs30 ingots manuf...