The extraction, preparation and safe storage of gadolinium oxide (Gd₂O₃) are important aspects of rare earth element processing. The following is a detailed description:

一、Extraction method of gadolinium oxide

Gadolinium oxide is usually extracted from rare earth ores containing gadolinium, common ores include monazite and bastnäsite. The extraction process mainly includes the following steps:

1.Ore decomposition:

The rare earth ore is decomposed by acid or alkaline method.

Acid method: Treat the ore with concentrated sulfuric acid or hydrochloric acid to convert the rare earth elements into soluble salts.

Alkaline method: Use sodium hydroxide or potassium hydroxide to melt the ore at high temperature to convert the rare earth elements into hydroxides.

2.Rare earth separation:

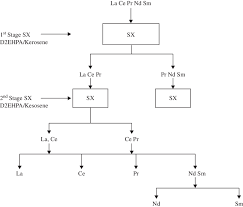

Separate gadolinium from mixed rare earth solutions by solvent extraction or ion exchange.

Solvent extraction method: Use organic solvents (such as tributyl phosphate) to selectively extract gadolinium ions.

Ion exchange method: Use ion exchange resin to separate gadolinium ions.

3.Purification of gadolinium:

Through multiple extractions or ion exchange, other rare earth elements and impurities are removed to obtain high-purity gadolinium compounds (such as gadolinium chloride or gadolinium nitrate).

4.Conversion to gadolinium oxide:

The purified gadolinium compound (such as gadolinium nitrate or gadolinium oxalate) is calcined at high temperature to decompose and generate gadolinium oxide.

Reaction example: 2 Gd(NO₃)₃ → Gd₂O₃ + 6 NO₂ + 3/2 O₂

二、Preparation method of gadolinium oxide

1.High temperature calcination method:

Calcine gadolinium salts (such as gadolinium nitrate, gadolinium oxalate or gadolinium carbonate) at high temperature (above 800°C) to decompose and generate gadolinium oxide.

This is the most commonly used preparation method and is suitable for large-scale production.

2.Hydrothermal method:

Gadolinium oxide nanoparticles are generated by reacting gadolinium salts with alkaline solutions under high temperature and high pressure hydrothermal conditions.

This method can prepare high-purity gadolinium oxide with uniform particle size.

3.Sol-gel method:

Gadolinium salts are mixed with organic precursors (such as citric acid) to form a sol, which is then gelled, dried and calcined to obtain gadolinium oxide.

This method is suitable for preparing nano-scale gadolinium oxide powder.

三、Safe storage conditions of gadolinium oxide

Gadolinium oxide is relatively stable at room temperature, but the following storage conditions should still be noted to ensure safety and material performance:

1.Moisture-proof:

Gadolinium oxide has a certain degree of hygroscopicity and should be stored in a dry environment to avoid contact with moisture.

It is recommended to use a sealed container and add a desiccant (such as silica gel).

2.Light-proof:

Gadolinium oxide is sensitive to light, and long-term exposure to strong light may affect its performance.

Should be stored in a cool, dark place.

3.Temperature control:

The storage temperature should be controlled within the range of room temperature (15-25°C), avoiding high or low temperature environments.

High temperature may cause structural changes in gadolinium oxide, and low temperature may cause hygroscopicity.

4.Avoid contact with acid:

Gadolinium oxide is an alkaline oxide and will react violently with acid.

Keep away from acidic substances during storage.

5.Prevent dust:

Gadolinium oxide powder may irritate the respiratory tract and skin.

Use sealed containers when storing and wear protective equipment (such as masks and gloves) when handling.

IV. Precautions

1.Toxicity: Gadolinium oxide itself is low in toxicity, but its dust may irritate the respiratory tract and skin, so direct contact should be avoided.

2.Waste disposal: Waste gadolinium oxide should be recycled or treated in accordance with the hazardous chemicals handling regulations to avoid environmental pollution.

Through the above extraction, preparation and storage methods, high-quality gadolinium oxide can be obtained efficiently and safely to meet its needs in the fields of magnetic materials, optical devices, medical imaging, etc.

Post time: Feb-28-2025